Sintered NdFeB maganadisuMagnet ne da aka yi daga Nd,Fe,B da sauran abubuwan ƙarfe.Yana tare da mafi ƙarfin maganadisu, ƙarfin tilastawa mai kyau.Ana amfani da shi sosai a cikin ƙananan motoci, injin janareta na iska, mita, na'urori masu auna firikwensin, lasifika, tsarin dakatarwar maganadisu, injin watsa maganadisu da sauran aikace-aikacen masana'antu.Sauƙin lalatawa a cikin mahalli mai laushi, don haka wajibi ne a yi jiyya ta saman bisa ga bukatun abokan ciniki.Za mu iya bayar da coatings, kamar Zinc, Nickel, Nickel-Copper-nickel, Silver, zinariya-plating, epoxy shafi, da dai sauransu Grade: N35-N52, N35M-48M, N33H-N44H, N30SH-N42SH, N28UH-N38UH, Saukewa: N28EH-N35EH

Tsarin Sintered Neodymium Magnet Manufacturing

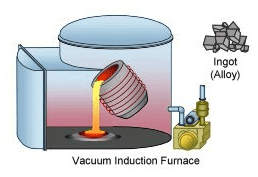

Kayan magnetic da sauran karafa ana fallasa su zuwa tsaka-tsaki kuma suna narke a cikin tanderun ƙaddamarwa.

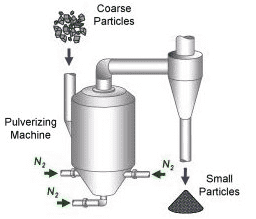

Bayan kammala matakai daban-daban na tsari, an juye ingots cikin ɓangarorin da ke da girman microns da yawa.Don hana oxidation daga faruwa, ƙananan ƙwayoyin suna kiyaye su ta hanyar nitrogen.

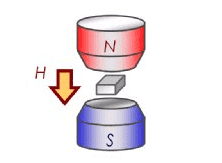

Ana sanya ɓangarorin maganadisu a cikin jig kuma ana amfani da filin maganadisu yayin da ake matsi da maganadisu cikin siffofi da farko.Bayan fara siffata, man isostatic latsawa zai ci gaba da samar da siffofi.

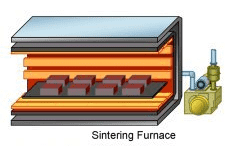

Ana sanya ɓangarorin maganadisu a cikin ingots waɗanda aka danna kuma za a yi maganin zafi a cikin tanderun da ke murƙushewa.Girman abubuwan da suka gabata kawai yana kaiwa kashi 50% na ƙimar gaske zuwa ƙetare.Amma bayan sinteing, ainihin yawa shine 100%.Ta hanyar wannan tsari, ma'aunin ingots ya kusan raguwa 70% -80% kuma an rage girmansa da 50%.

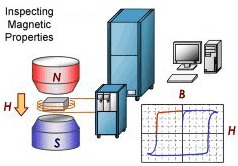

An saita mahimman kaddarorin maganadisu bayan an kammala ayyukan sintiri da tsufa.Ana yin rikodin babban ma'auni ciki har da ragowar juzu'i, tilastawa, da matsakaicin samfurin makamashi.

Waɗancan maganadiso waɗanda suka wuce binciken ana aika su zuwa matakai masu zuwa, kamar injina da haɗawa.

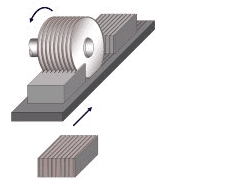

Saboda raguwa daga tsarin sintiri, ana samun ma'aunin da ake buƙata ta hanyar niƙa maganadisu tare da abrasives.Ana amfani da abrasives na lu'u-lu'u don wannan tsari saboda magnet yana da wuyar gaske.

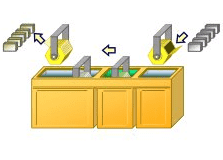

Don mafi dacewa da yanayin da za a yi amfani da su, ana yin maganadisu daban-dabansaman jiyya.Nd-Fe-B maganadiso gabaɗaya suna da saurin kamuwa da tsatsa tare da bayyanar da ake bi da su azaman NiCuNi magnet, Zn, Epoxy, Sn, Black Nickel.

Bayan plating, za a yi ma'auni masu alaƙa da dubawa na gani don tabbatar da bayyanar samfurin mu na maganadisu.Bayan haka, don tabbatar da daidaitattun daidaito, muna kuma buƙatar gwada masu girma dabam don sarrafa haƙuri.

Lokacin da bayyanar da girman jurewar maganadisu suka cancanta, lokaci yayi da za a yi magnetization shugabanci.

Bayan dubawa da magnetize, maganadisu suna shirye don shiryawa tare da akwatin takarda, har ma da pallet na katako kamar kowane buƙatun abokan ciniki.Magnetic Flux na iya keɓe shi ta ƙarfe don iska ko lokacin isarwa.

Lokacin aikawa: Janairu-25-2021